GP27 / GP35 Series CNC Cylindrical Grinding Machine (Plunge Type)

Accessories

Specifications

Plunge type GP27 Series

|

MODLE

|

GP27 / 35-400CNC | GP27 / 35-600CNC | GP27 / 35-800CNC | ||

|---|---|---|---|---|---|

| Work capacity | Maximum grinding diameter | mm | 270/350 | ||

| Distance between centers | GP | 400 | 600 | 800 | |

| Distance from spindle hole center to the slide | mm | 136/176 | |||

| Maximum workpiece weight | kgs | 120/150 | |||

| Grinding wheel | Grinding wheel size | mm | ψ405x32~50xψ152.4(opt.ψ455x50~80xψ152.4) | ||

| Rotating speed of grinding wheel spindle | rpm | 1650(1890) | |||

| Maximum peripheral speed | m/sec | 35(45)m/sec | |||

| Wheel head | Feed angle | deg | GP=90,GA=60 | ||

| Maximum feed rate | mm | 6m/min | |||

| Minimum setting unit | mm | 0.001 | |||

| Total stroke | mm | 250 | |||

| Head stock | Spindle speed | rpm | 10~600 | ||

| Center taper | MT | MT4 | |||

| Spindle through hole diameter | mm | 25 | |||

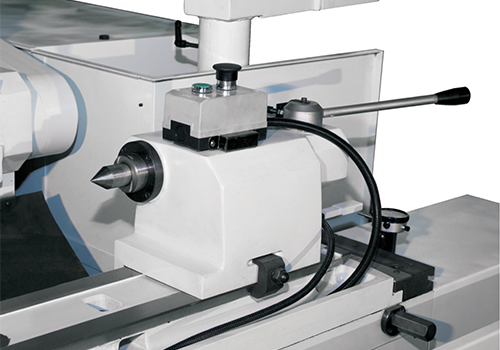

| Tailstock | Sleeve stroke | mm | 30 | ||

| Center taper | MT | MT4 | |||

| Worktable | Swivel angle | deg | -8~+11 | -6~+9 | -4~+7 |

| Rapid traverse speed | mm | 6m/min | |||

| Minimum setting unit | mm | 0.001 | |||

| Motor | Grinding wheel spindle motor | hp | 5(7.5) | ||

| Head stock motor | kw | 1.0(1.5) | |||

| Hydraulic motor for grinding wheel spindle | hp | 1/8 | |||

| Coolant pump motor | hp | 1/4 | |||

| X-axis feed servo motor | kw | 1.0(1.2) | |||

| Z-axis feed servo motor | kw | 1.5(1.8) | 1.5(1.8) | 1.5(1.8) | |

| Control system | MITSUBISH(FANUC) | ||||

| Net weight (approx.) | kgs | 2600 | 3000 | 3400 | |

| Gross weight (approx.) | kgs | 2800 | 3200 | 3600 | |

| Packing size(L*W*H) | mm | 2400x1900x2000 | 2800x1900x2000 | 3200x1900x2000 | |

*We reserve the right to modify any machine specifications without prior notice.

| Standard accessories | ||

|---|---|---|

| Grinding wheel and flange * 1 set | Workpiece drive ring * 1 set | Standard water tank and pump |

| Grinding wheel dismounting device * 1 | Balancing stand and arbor * 1 set | Grinding wheel inverter |

| Diamond dresser * 1 set | MT4 center * 2 pieces | Gap elimination anti-collision device |

| Toolbox * 1 set | Heat exchanger in electric box | Quartz work lamp |

| Optional accessories | ||

|---|---|---|

| X-axis digital readout | Manual 3-jaw chuck | 2-point center rack |

| Z-axis digital readout | Oil mist collector | 3-point center rack |

| Outer diameter measuring device | Magnetic separator | Workpiece support rack |

| Automatic grinding wheel balancer | Paper filter | Grinding wheel suspending rack |

| Hydraulic tailstock | Air conditioner in electric box | Grinding wheel hanger |

| Manual 3-jaw chuck | ||