KG-500 CNC Internal External Cylindrical Compound Grinding Machine

CNC Internal External Cylindrical Compound Grinding Machine

- Dual grinding spindle

- Available for turning spindle

- Max. grinding length 200mm

- Fanuc controller

- Full splash guard

- X, Y, Z axis stroke 400/350+200/350+200mm

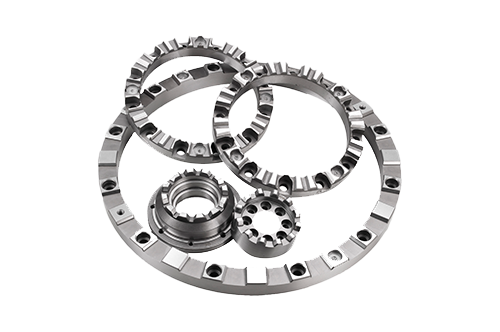

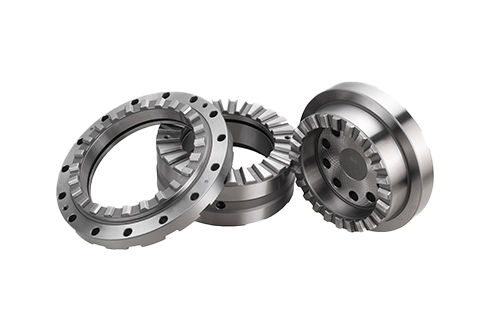

The KG-500 machine model is a dual-axis internal diameter grinding machine with two independent internal spindle units. This model is suitable for processing workpieces with large machining travel and a wide grinding range, capable of handling workpieces with a diameter of 400 or more.

High accuracy linear ways and ball screw for X, Z axis, to guarantee ultra precision and rigidity.

Base structure apply to FC30 cast iron, with tempered and stress released to guarantee machining accuracy and stability.

Oversized machine base with internal rids running throughout each section base on Machanics, featuring long term metallic rigidity and stability.

X, Z axis are both driven by servo motor with min display 0.0001mm.

Dual grinding spindle

Grinding spindle + lathing module

- With powerful function to set up parameters for multiple faces grinding

- Avaialble to excute 16 faces grinding with 1 set up

| Type | KG-500 | |

|---|---|---|

| Working Capacity | Grinding dia, range | Ø 4 ~ Ø 320mm |

| Max, grinding depth | 200 mm | |

| Max, swing range of workpiece | Ø 450mm | |

| Swing range within the water proof cover | Ø 300 mm | |

| Controller System | Controller | FANUC |

| Workhead | Spindle speed | 0 ~ 1000 rpm |

| X-axis feedrate / Max stroke | 10 M/min / 400 mm | |

| X-axis minimum display unit | 0.0001 mm | |

| Swiveling angle | -5˚~+30˚ | |

| Worktable | Y-axis & Z-axis feed rate | Y : 10 / Z :10 M/min |

| Y-axis & Z-axis max. stroke | Y : 350+200 / Z : 350+200 | |

| Y-axis & Z-axis minimum display unit | Y : 0.0001 / Z : 0.0001 | |

| Distance from spindle center to the ground | 1100 mm | |

| Hydraulic System | Oil Tank Capacity | 30 L |

| Cooling System | Coolant Tank Capacity | 250 L |

| Motor | Hydraulic motor | 0.75 Kw (1HP) |

| Coolant pump motor | 0.18 Kw (1/4HP) | |

| X-axis & Z-axis servomotor | X : 1.6 Kw / Y : 1.6 Kw / Z : 1.6 Kw | |

| Grinding wheel motor (kw) | Y : 4.0 , (5HP) Z : 4.0 , (5HP) |

|

| Spindle motor | 2.2 , (3HP) | |

| Others | Automatic lubricator | 4 L |

| Machine dimension (LxWxH)-including accessories | 3450 x 2150 x1900 mm | |

| Machine Weight | 4750 kg | |

| Standard accessories | CNC Controller | |

| Inverter for X-axis workhead motor | ||

| Inverter for Z-axis grinding spindle motor | ||

| Inverter for Z2-axis grinding spindle motor | ||

| Y-axis grinding spindle | ||

| Z-axis grinding spindle | ||

| Hydraulic chuck | ||

| Hydraulic cylinder | ||

| Tricolor alarm lamp | ||

| Working lamp | ||

| Tool box | ||

| Automation lubrication | ||

| Coolant tank and pump | ||

| Paper filter | ||

| Magnetic separator | ||

| Hydraulic tank with pump | ||

| Internal heat radiation system inside cabinet | ||

| Diamond Dresser | ||

| Leveling bolts and pads | ||

| Mechanical, electrical operation manuals | ||

| Fully-enclosed cover | ||